Choosing the appropriate environmental test chamber manufacturer is undoubtedly an important decision for any firm that has product development and testing among its activities. These custom chambers are key elements in the trustworthiness and the endurance of the products functioning under diverse environmental conditions. The situation on the market is very competitive now as there are many producers in the market. Such selection is really a challenging job and nobody can manage to make the right decision without taking the time to ponder it. This article aims to equip you with priceless tips that will be helpful to you as you make up your mind on the manufacturer you should choose for an environmental test chamber.

Understand Your Testing Requirements

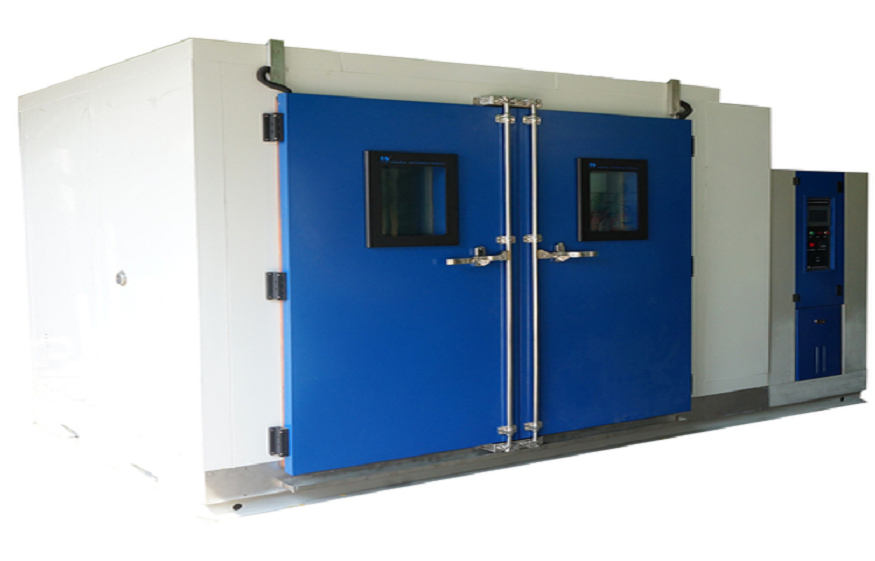

The first step to choosing the right environmental test chamber manufacturer is to outline the essential parameters of your testing needs. Try and find out the what conditions your products needs to be tested under that includes such as temperature, humidity, vibration, or altitude. Figure out what size and what capacity of the chamber is needed, and if any special features or customizations need to be designed to be added. Being clearly aware of your testing restraints will help you to shorten the list of potential manufacturers and make sure that the selected product has all the required specifications.

Studies Production history and skill sets.

In getting environmental test chamber makers, one should never be afraid to ask about their specifics as well as their commitments and capability to sustain the quality products produced. Restaurant owners will therefore need to find suppliers who can be trusted in the business, who are well known for producing high quality products and whose clients are satisfied. Certifications, like ISO, NIST or ISTA must be confirmed to be true. This implies that they are flexible enough to adjust to the latest modern technological methods and measures of quality by default. In addition, you should investigate the type of environmental test chambers they have, their ability to customize options, and their technical assistance in answering your questions.

Evaluate Product Quality and Durability

The most important factors to focus on when selecting an environmental test chamber include the quality and durability of the chamber itself. Evaluate the materials employed for the chamber fabrication, the precision of the parts as well as the performance of the entire unit. Quality is the key factor, so see brands that use certified high quality materials and practice strict quality control policy to guarantee the quality and reliability of the product over time. In this way, you shall be able to prevent expensive downtime and keep your testing environment unchanged and accurate all the time during the entire product development.

Consider Maintenance and Support

Sustainability of working testing chambers is one of the most important issues related to environmental test chambers and their uninterrupted operation. Assess the warranties and technical support service of the manufacturer. Find the environmental test chamber manufacturers who offer a wide range of support from preventive maintenance to repair of the components and also have a customer support team that is very responsive. It follows that any problems encountered as well as malfunctions are immediately to be tackled, thereby, reducing the downtime and protecting the relevant environment of the testing process. Furthermore, factor in the availability of spare parts and the convenience of sourcing these parts, since they can be the main contributors to the chamber’s long-term operation efficiency.

Keep Energy Efficiency and Sustainability

In the present time, when it is a pressing matter to find answers to the energy inefficiency and sustainability issues, it is wise to think about the environmental test chamber that will be more energy efficient. Opt for producers with energy-efficient products as their main focus, for example, modern insulation systems, energy-saving compressors, and smart control units. Such factors are capable of decreasing the energy usage of the chamber, cutting your costs and, at the same time, contributing to your sustainability targets. Furthermore, evaluate the environmental effects of manufacturing the chamber as well as the decomposition when the chamber is no longer usable.

Evaluate the Manufacturer’s Commitment to Innovation

As the product testing space is dynamically evolving, it is imperative to work with a company that is dedicated to forward-thinking and to stay ahead of industry shifting. Search for brands that are serious about research and development, constantly working on the designs and technology of their environmental chamber as well as employing the most modern technology. This is what commits you to not only the innovation itself but also, to the access to the latest solutions that can offer you a competitive advantage in the testing and development processes of your products. Besides, an outlook-minded manufacturer would most probably provide you with the solutions that might be able to change with your evolving requirements.

The manufacturer proximity and logistical support

Both the physical location of the environmental test chamber manufacturer and the high quality of their logistics support can determine how your test procedures are going to be running. Consider working with suppliers that are physically located nearby your facilities, this can be useful in decreasing the transportation costs and lead times for delivery, installation, and maintenance. Besides that, make a comparison of the manufacturer’s logistics skills, including how fast they can deliver, the installation process, and if they have helpful manuals. It will allow you to avoid major problems with your testing timeframe and keep the environmental test chamber compliant with the installation.

Conclusion

The selection of an appropriate environmental test chamber manufacturer is a critical measure that can sometimes lead either to a successful project or to a failure. Through the consideration of the factors discussed in this article including the identification of the testing requirements, the assessment of the manufacturer credentials and capabilities, and the prioritization of energy efficiency and customization, you will be able to make a decision that is congruent with your organization’s needs and long-term goals. Through the cooperation with a trusted and sound environmental test chamber maker, you can strengthen the reliability of the performance of your products and be able to access the market with an advantage against your rivals.