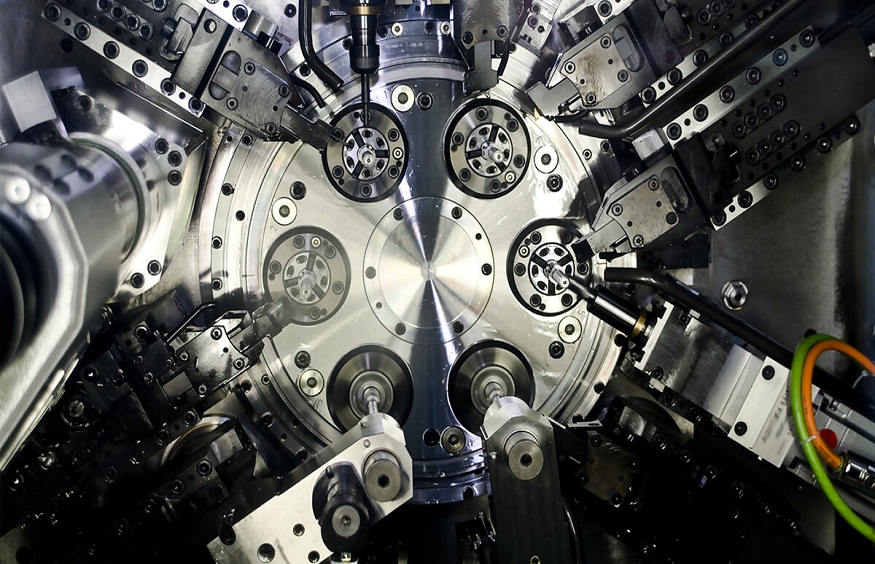

Machine tools are regarded as an essential element of the contemporary manufacturing system. They ease tasks, simplify procedures, and make them swifter and more efficient. A machine tool is any device for shaping or forming metal or any other material into certain shapes. These were used long ago, but advanced modern technology has engineered them to meet even more demands and uses. In this article, we discuss the advantages that machine tools provide for production processes within industries.

What Are Machine Tools?

Machine tools are machines that perform mechanical operations such as cutting, drilling, grinding, and shaping. These machines use electricity or human effort to carry out their functions. They form a vital aspect of industries producing other parts and products in the automotive, aerospace, electronics, and construction industries, among others.

Important Benefits of Using Machine Tools

1. Precision and Accuracy are Very High

One of the most important advantages of machine tools is their capability for accuracy. Machine tools minimize the possibilities of error as compared to manual workings, which are prone to human mistakes because of the accurate measurements and precise cutting techniques. Such accuracy is necessary when part manufacture is required to fit perfectly inside other machines or products.

For example, in aerospace or electronic firms, even a minute error leads to failure. Machine tools reduce the probability of such a thing happening by ensuring that each of the products is manufactured to the precise measurement.

2. Faster Production Time

Machines speed up the manufacturing process more rapidly than human beings. Unlike manual work, which consumes time and effort, machine tools produce many parts at a rate faster than that of manual work. There are automated machines that operate for long periods without resting; thus, one saves time and produces more quickly in faster production.

With such speed, companies will be able to fulfill high demands without compromising the quality of what they make. Most of the time-sensitive companies, such as the automotive manufacturing sector, can use machine tools that enable them to produce products in the shortest time.

3. Quality Control

Quality is a component of any production process. Machine tools aid in quality control because they enable uniform performance throughout an entire production run. These tools ensure that each item has the same quality since the same tolerance may exist in different parts produced in large quantities by a company.

Machine tools also facilitate the easy discovery of problems when production is being done. The problem would have been identified at such stages as well as dealt with at such stages that would influence the final product. In this way, there would be fewer defects and higher-quality products.

4. Cost Efficiency

This means that machine tools can also help to reduce the production cost. Although great investment may be required in setting these tools, long-term gains outweigh short-term profits. They increase efficiency and decrease manual labour, and hence the savings can be huge.

Since machine tools are accurate and precise, less waste of materials will occur, which is simply the reduction of waste of raw materials, energy, and labour by companies using them in a production process.

5. Safety of Workers

Machine tools make manufacturing safer for the workers. Manual operations entail operating with sharp materials, heavy goods, or dangerous chemicals, which could be a hazard. Machine tools take up these operations, and thus the risk of accidents and injuries is reduced.

Automatic machines allow operators to work from a distance or in a safe, regulated environment so that danger can be avoided. In this way, the workplace becomes safer and more comfortable for employees.

6. Flexibility and Customization

Machine tools are versatile. Enterprises can drill, cut, or bend materials using these machines. One may require the drilling of holes in materials, while another company might require the cutting and bending of material parts. An industry requires a custom-made requirement or product requirement, in which case machine tools come in handy.

Let’s consider the example of an auto manufacturer that requires designing specific parts for various vehicles. With proper programming, these machine tools can create these parts precisely at a tremendous speed, which makes it easier and more efficient to customize such products.

Benefits of Sheet Metal Bending Tools

Among the most common operations in metalworking is sheet metal bending. Here, you bend flat sheets of metal into various shapes, which may then be used for car parts, machinery, building materials, and so on. Tools for sheet metal bending are designed specifically to make this easier and more efficient.

1. Precise bending

Sheet metal bending tools bend with a lot of precision without damaging the metal. The varied angles at which they bend metals make it possible to create parts with various specific shapes. Accuracy in the tools ensures that every bend is accurate, minimizing the occurrence of errors or waste.

2. The Fast-Bending Process

Metal sheets bend laboriously as a result of human bending. The use of bending tools saves the time of the workers so that bending of sheets can be done within seconds. Quick execution is often required in most industries regarding a very large quantity of metal parts within a short period.

3. Cost Savings

Another way it helps cut costs is through using sheet metal bending tools. These lessen the manpower use so that a company has more time to save on cost. Moreover, being very precise, these tools bring about less waste; hence, fewer material costs would be incurred.

4. Safety

As seen with other machine tools, sheet metal bending tools assure a safer environment at work. Bending the metal sheets is made easier and workers are less likely to get injured during this process. It also becomes faster and safer for employees.

Conclusion

Modern manufacturing, therefore, relies on machine tools for efficiency. These can ensure more accuracy, faster production, better safety aspects, and saving costs. More specifically, heavy metalworking industries rely on such equipment to serve them with quality products made. Of great importance in metalworking are those bent sheet metal bending tools that have a significant role in shaping the sheet and making it bend to produce an accurate shape, safe, and versatile.

Manufacturers use machine tools and Sheet metal bending tools to uphold production quality while keeping it cost-effective and safe. These tools have transformed manufacturing and are now creating the future of manufacturing for many industries.